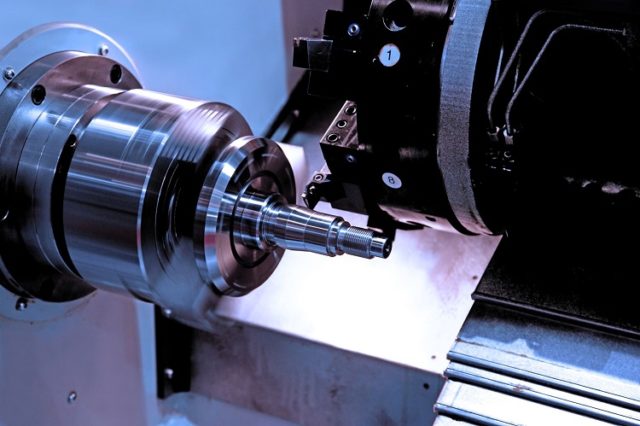

Here at Modus we are often asked the question “what is precision machining?” Precision machining in its basic form is taking a larger piece of material and cutting off the excess to create a smaller piece of material. The larger piece of material is changed in some way using a material removal procedure. This small piece of material will fit exactly where needed and can be used to smoothly carry out its desired task. Generally it will involve cutting materials into exact shapes and sizes and as such a wide range of machinery is used.

In the early days of precision machining workers would still try to achieve the highest level of accuracy. This was achieved even with the use of relatively rudimentary tools such as blades, saws and hammers. However, as technology advanced so did the techniques, methods and in turn the degree of accuracy. The processes can be used upon a variety of materials including metal, wood and plastic.

Computer Numerical Controlled (CNC) is a process used widely throughout precision machining. It uses numerical control which can be customised throughout every job and controls numerous tools such as lathes, mills and grinders. The use of computers helps to eliminate any possibility of error, the design will be loaded onto the computer and then transformed in a precision process. There is a wide variety of CNC services available here at MNB Precision including turning and milling. There are many benefits associated with the use of CNC. These can include: